The fuel pressure regulator plays a vital role in the sophisticated fuel system of an automotive engine. It directly affects several key aspects of engine performance, fuel economy, and exhaust emissions. However, in the face of a wide range of products on the market, how do you choose the right fuel pressure regulator for your car? In this article, we will provide you with a detailed analysis from multiple dimensions to help you pinpoint the ideal choice in the vast market.

Ⅰ. Matching and Screening: Pinpointing Your “Ideal” Fuel Pressure Regulator

1. Precise Matching of Vehicle Models and Part Numbers

Fuel system design, piping connections, and pressure settings may vary from brand to brand, model to model, and even from year to year for the same model. Therefore, the surest way is to consult your vehicle’s service manual to find the original factory-specified part number, or utilize a reliable auto parts lookup system and enter your model year information (year, make, model, engine code, etc.) to get an accurate compatible part number. For example, the product list we referenced for the Nissan Cefiro, Maxima, Elgrand, Sunny, and Infiniti G35 has a part number of 22670-2Y500, while the one for the RW Marvel X is 16207-83189, which should never be mixed. This precise matching is the first line of defense to ensure a smooth installation and proper function.

2. Actual Vehicle Usage and Performance Requirements

If your vehicle is a daily driver that doesn’t require much power, opt for a reliable fuel pressure controller that meets factory standards. But if you’ve modified your vehicle for more power, like increasing engine displacement, adding a turbocharger, or using higher-grade fuel with ECU tuning, the factory pressure setting may not suffice. Then, consider an adjustable fuel pressure regulator or one with slightly higher pressure than stock. Adjustable regulators have extra screws for manual pressure adjustment within a range, offering performance optimization flexibility. However, adjusting pressure requires expertise and equipment like a fuel pressure gauge for accuracy. Blind adjustments may cause problems.

Ⅱ. Manufacturing Process and Fuel Pressure Regulator Supplier Selection

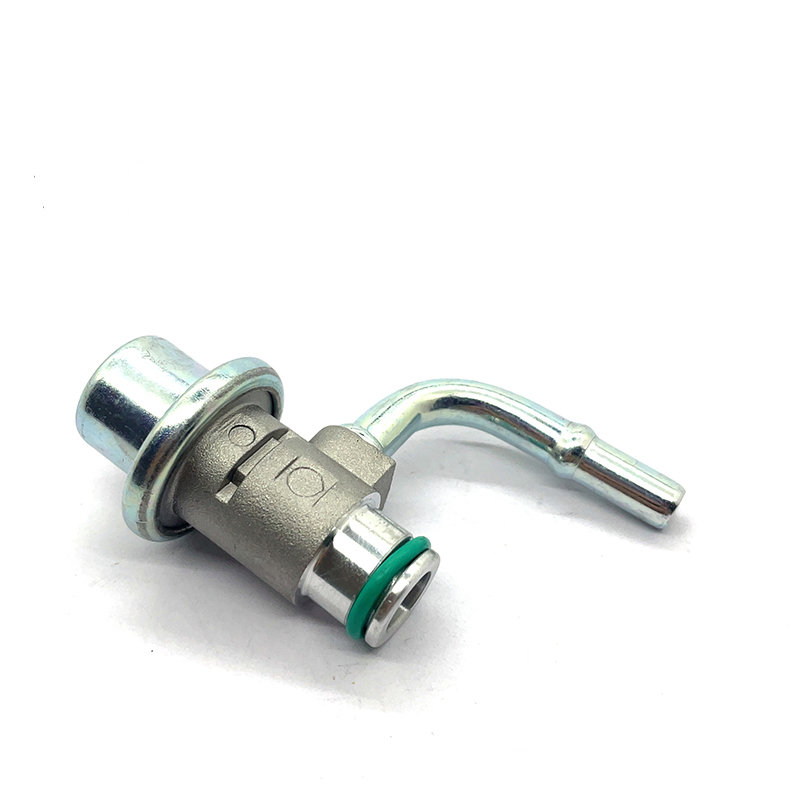

High-quality fuel pressure regulators are often made of durable metal materials like aluminum alloy. These materials can resist corrosion and handle high pressure. They also have high-quality internal springs and seals to ensure long-term stable operation. However, some low-quality products might use plastic or inferior metal. These materials are more likely to deteriorate, deform, or get damaged in tough working conditions, like high temperatures or prolonged fuel exposure. This can lead to leaks or regulation failures. Although it is impossible to judge visually, choosing reputable brands and suppliers can avoid this risk to a certain extent.

When choosing suppliers of fuel pressure controllers, consider those who provide detailed product information, have good user reviews and after-sales protection, and tend to have stricter control over product quality. These suppliers usually list key information such as materials, specifications, performance parameters, and scope of application in their product manuals, so that consumers can have a more in-depth understanding of the product. Meanwhile, suppliers with good after-sales service are also trustworthy.

Perfect after-sales service should cover more than just the three-pack policy on product quality. It also needs to include product consultation, technical support, and after-sales maintenance. When consumers meet with problems during use, they can get professional guidance and timely solutions from the supplier. This offers extra security for product use. In summary, by taking into account brand reputation, user reviews, product information transparency, and after-sales service, consumers can accurately identify quality fuel pressure regulator suppliers. Then they can choose a reliable and durable “guardian” for their car’s fuel system.

Ⅲ. Installation and Maintenance of Fuel Pressure Regulator: Ensuring Long-term Stable Operation

Even the best fuel pressure controller will not be able to fulfill its proper performance if it is not properly installed or maintained. During installation, it is essential to strictly follow the operating instructions in the product manual. The high-standard design of the fuel pressure regulator incorporates standardized quick-connect interfaces and a tool-free disassembly structure, significantly enhancing installation convenience. However, it is still recommended that installation be performed by professional service personnel to ensure the integrity of the fuel system’s seals and the precision of pressure regulation.

Regular maintenance checks are the secret to prolonging the life of the regulator. It is recommended that the regulator’s critical connections, including vacuum ports, fuel line connections, and seals, be inspected every 15,000 – 20,000 kilometers or annually to prevent the risk of unstable pressure and fuel leakage due to looseness, damage, or deterioration. Also, when cleaning the regulator housing, avoid using aggressive cleaning agents that may damage the seals and housing coating.

Ⅳ. Conciusion

Selecting the right fuel pressure controller involves considering precise fit, brand reputation, parameter performance, and ease of maintenance. It’s crucial for your car’s engine to ensure stable and efficient fuel supply in different conditions. This article’s analysis aims to help you navigate the market and find the perfect “behind-the-scenes regulator”. With it, your engine will perform well and remain stable on every journey, making your trips smooth and worry-free.