The fuel system of a vehicle is located within the heart of the vehicle- the engine from where it derives a steady supply of power for its operation. In between that intricate system, there lies one seemingly insignificant but critically important component, the fuel pressure regulator. It is this small device that in silence regulates the fuel pressure to the engine’s supply of optimal fuel. Even the most advanced engines will not reach their full potential without the precise regulation that is neeeded from the fuel pressure controller. So, does the fuel pressure controller really control the automotive engine fuel system? This paper will try to interpret the role of the fuel pressure controller from the working principles, importance, and impacts on the performance of the vehicle and relate it to the present situation in the automobile industry.

I. Automotive Engine Fuel System: A Precision-Engineered Energy Delivery Chain

The modern automotive engine fuel system is a highly coordinated precision engineering system whose core mission is to deliver fuel stored in the fuel tank to the combustion chamber at precise pressure, in a clean state, and at the appropriate time. This system primarily includes:

- Fuel Tank: The storage container for fuel.

- Fuel Pump: The core power source, which pressurizes and pumps fuel from the fuel tank.

- Fuel Filter: A critical component that filters impurities and moisture from the fuel, protecting downstream precision components.

- Fuel Rail: A pressure vessel that stores and distributes high-pressure fuel to the injectors.

- Injectors: The execution terminals that precisely control fuel injection volume, timing, and atomization based on ECU instructions.

- fuel pressure regulator: The core control unit of the fuel system, ensuring the system pressure is always maintained at the optimal set value.

The fuel tank acts as a large “fuel reservoir,” storing the fuel required for the vehicle’s operation. The fuel pump functions like an tireless “fuel transporter,” drawing fuel from the tank and pressurizing it for delivery through the fuel lines. The fuel filter acts like a meticulous “gatekeeper,” filtering out impurities in the fuel to prevent them from entering the engine and causing damage. The fuel injector functions like a precise “syringe,” spraying fuel in a mist into the cylinder according to the ECU’s instructions, mixing it with air to prepare for combustion.

In this system, the fuel pressure regulatorplays a crucial role. It acts like a “pressure control valve,” connected between the fuel rail (fuel distribution pipe) and the intake manifold, responsible for regulating the fuel pressure in the fuel rail to maintain it within a stable range. This pressure range is typically pre-set by the vehicle manufacturer based on the engine’s performance requirements.

II. The Mystery Behind Pressure: How the Fuel Pressure Regulator Works

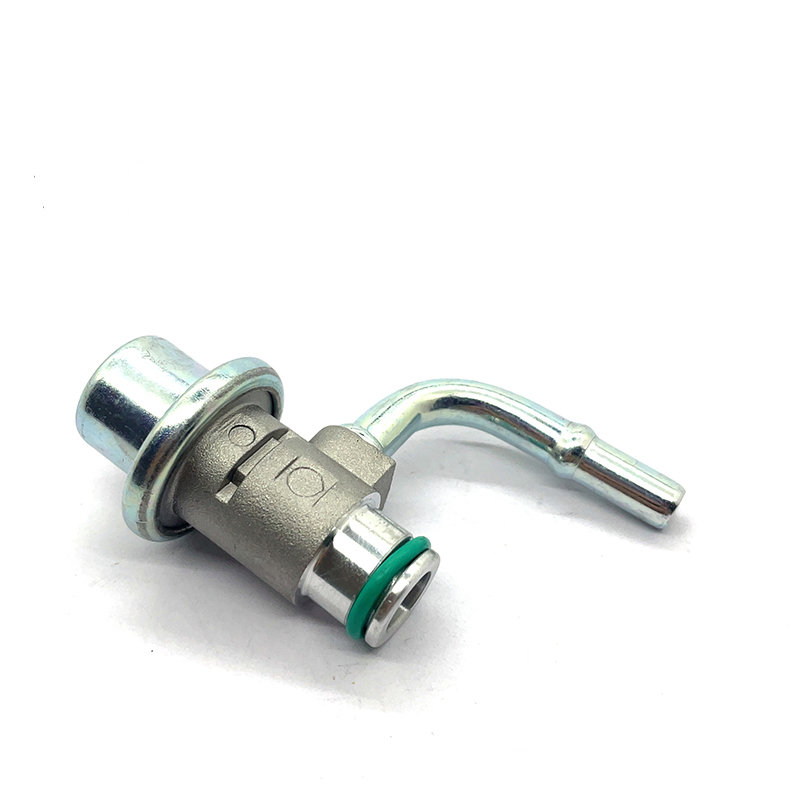

Although the fuel pressure controller has a simple structure, its working principle involves precise mechanical control technology. Taking the traditional mechanical fuel pressure controller as an example, it primarily consists of components such as a diaphragm, spring, valve core, and return port.

The diaphragm divides the interior of the fuel pressure controller into upper and lower chambers. The upper chamber is connected to the intake manifold via a vacuum tube and bears the intake manifold pressure; the lower chamber is connected to the fuel rail and bears the fuel pressure. The spring acts on the diaphragm to provide the set pressure. When engine conditions change, the intake manifold pressure varies, causing the diaphragm to become unbalanced, which moves the valve core to regulate the return oil flow, thereby stabilizing the fuel system pressure.

When the engine is running, the fuel pump pressurizes and delivers fuel to the fuel rail, increasing the pressure inside the fuel rail. Meanwhile, the vacuum pressure in the intake manifold also changes with the engine’s operating conditions. When the intake manifold vacuum pressure increases (e.g., during idle operation), the pressure above the diaphragm decreases, and the spring’s force pushes the valve core toward the return port, increasing the return flow area. More fuel flows back from the fuel rail to the fuel tank through the return port, thereby reducing the pressure in the fuel rail.

Conversely, when the vacuum pressure in the intake manifold decreases (e.g., during acceleration), the pressure above the diaphragm increases, overcoming the spring force to push the valve core toward the fuel rail, reducing the return fuel passage area and decreasing the return fuel flow, thereby increasing the pressure within the fuel rail.

In this way, the fuel pressure regulator dynamically adjusts the pressure within the fuel rail based on changes in intake manifold pressure, maintaining it within a relatively stable range. This range is typically slightly higher than the intake manifold pressure to ensure proper operation of the fuel injectors.

As car tech progresses, electronic fuel pressure controllers are becoming more common in modern vehicles. They use an electronic control unit (ECU) to manage an electromagnetic valve, which allows for highly accurate fuel – pressure control. These regulators can swiftly respond to changing engine conditions and make precise adjustments. As a result, engine performance and fuel economy are enhanced.

III. The Foundation of Performance: The Impact of Fuel Pressure Regulators on Vehicle Performance

Although fuel pressure regulators are compact in size, their impact on vehicle performance should not be underestimated. By precisely regulating fuel pressure, they directly influence the fuel injection volume and timing of the fuel injection system, thereby significantly affecting the engine’s power, fuel efficiency, and emissions performance.

1. Ensuring Power Performance

The power output of an engine depends on the fuel-air mixture ratio and combustion efficiency within the combustion chamber. A high-sensitivity fuel pressure regulator maintains stable pressure within the fuel rail, ensuring that the injectors spray appropriately atomized fuel and mix it thoroughly with air. During acceleration or high-load conditions, the fuel pressure controller can quickly increase fuel pressure, enabling the injectors to spray more fuel to meet the engine’s power requirements, thereby improving the vehicle’s acceleration performance and hill-climbing capability.

2.Reduce fuel wastage

In the course of idling or low-load conditions, the engine does not need to use as much fuel. It is here that the fuel pressure regulator lowers the pressure in the fuel rail and cuts down the amount of fuel that injectors put in, thereby stopping waste of fuel and improving its economy. A properly working fuel pressure controller allows an engine to run at ideal economic parameters, hence reducing consumption of fuel and operating costs of a vehicle.

Insufficient combustion of fuel in the engine increases pollution from the vehicle. It increases harmful exhaust wastes, reduces fuel efficiency, and damages engine performance. The fuel pressure regulator solves this problem by precisely controlling the pressure of the fuel. It makes certain that the fuel injection system supplies the proper amount of fuel for whatever load is placed on the engine. This in turn allows complete combustion of the cylinder fuels. As a result, harmful gas emissions such as carbon monoxide and hydrocarbons are reduced.

The fuel pressure regulator also controls pressure in the fuel rail, avoiding leakage and evaporation of fuel due to high pressure. This saves fuel from being wasted and reduces pollution further still in respect to emissions caused by evaporation of fuel, thus playing a most significant role in improving air quality and achieving environmentally friendly transportation.

Ⅳ. Selection and Maintenance: Fuel Pressure Regulator Suppliers and Tips on Maintenance

Since the fuel pressure controller plays a critical role in automotive engine fuel systems, it is important to have a reliable fuel pressure controller. With so many suppliers in the market, though, choosing the right one has become quite a challenge for vehicle owners and maintenance personnel.

1. Supplier Should Be Reputable

Choose reputable suppliers of fuel pressure controllers in the market. These suppliers will normally implement strict quality control systems and offer reliable, stable-performing fuel pressure controllers. You can check the reputation and credibility of a supplier through online searches, industry forums, or friends’ recommendations.

2. Product Quality and Certification

Corrosion-resistant materials production and testing inspection should fuel pressure controllers of quality. And in the purchase, check if the product has passed relevant quality certifications today, such as ISO 9001 quality management system certification. Also, review the product manual and warranty_policy so that you can know its performance parameters and service life.

4. Choose a Product Compatible with Your Vehicle Model

Different car engines have varying performance requirements for fuel pressure controllers. When purchasing, select a fuel pressure controller compatible with your vehicle model to ensure it functions properly and performs optimally. You can refer to the car maintenance manual or consult professional automotive technicians to determine the required model and specifications for your vehicle’s fuel pressure regulator.

In addition to selecting the appropriate fuel pressure controller, regular maintenance and upkeep are also crucial. The following are some key maintenance points for fuel pressure controllers:

Regular inspection: It is recommended to inspect the fuel pressure controller periodically (e.g., each time the engine oil is changed) for any damage, leaks, or other issues. Additionally, a fuel pressure gauge can be used to check whether the pressure within the fuel rail is normal.

Cleaning: The vacuum tubes and return ports of the fuel pressure controller are prone to carbon buildup and blockages, which can affect their normal operation. You can use carburetor cleaner to regularly clean these areas to keep them clear.

Replacement: As a wear-and-tear part, the fuel pressure controller has a limited service life. If you notice abnormal operation of the fuel pressure controller, such as reduced engine power, increased fuel consumption, or excessive emissions, it should be replaced promptly.

V. Intelligent Control and the Evolution of Fuel Pressure Regulator

With the development of automotive intelligence and connectivity, traditional mechanical and electronic fuel pressure controllers are also gradually evolving toward intelligent systems. Future fuel pressure regulators will no longer be standalone components but rather nodes within the vehicle’s intelligent control system, working in conjunction with other sensors and actuators to achieve more precise and intelligent fuel control.

1.Deep Integration of Fuel Pressure Regulator and Engine Control Unit

Future fuel pressure regulators will achieve tighter integration with the engine control unit (ECU) through data exchange via communication protocols such as CAN bus. The ECU can adjust the operating state of the fuel pressure controller in real-time based on information from various sensors (e.g., oxygen sensors, airflow meters, throttle position sensors, etc.), enabling more precise control of fuel injection.

2. Adaptive Learning Function

Future fuel pressure controllers will use AI for adaptive learning. They’ll learn the driver’s habits and the vehicle’s environment. Based on this, they’ll automatically adjust fuel pressure to boost engine performance and fuel efficiency. For instance, if a driver often travels on busy city roads, the system will lower fuel pressure. This change helps the engine work better in low – load situations.

3. Predictive Maintenance

Future vehicles can monitor the fuel pressure controller’s data in real time. They can predict when it might fail and alert the driver. This way, the driver can fix or replace it before any actual failure. This helps prevent engine issues or other problems caused by a faulty fuel pressure controller.

Ⅵ. Conciusion

The fuel pressure controller is not the “controller” of the automotive engine fuel system but rather a “fine-tuner.” By sensing the engine’s operating state, it dynamically adjusts fuel pressure to ensure the fuel injection system always provides the appropriate fuel volume matching the engine load, thereby guaranteeing the engine’s power, fuel efficiency, and emissions performance. Though its work is unnoticed, it is a crucial safeguard for smooth vehicle operation.

From mechanical to electronic, and toward future intelligent fuel pressure controllers, this small component has witnessed the continuous advancement of automotive technology. As the automotive industry progresses, fuel pressure controllers will continue to evolve, contributing even more to enhancing vehicle performance and environmental protection. As car owners and automotive technicians, we should also gain a deeper understanding of and place greater importance on the role of fuel pressure controllers. Choosing high-quality fuel pressure regulator suppliers and conducting regular maintenance and inspections not only helps keep your vehicle free from fuel system issues but also ensures the engine’s full potential is unleashed, guaranteeing smooth starts, swift acceleration, and efficient fuel conversion with every drop. In the future of rapidly advancing automotive technology, regardless of how forms evolve, the core mission of precisely regulating fuel pressure will remain the irreplaceable value of fuel pressure controllers.