In the fuel system of an automobile, the fuel pressure regulator plays a crucial role. It not only affects the engine’s power output and fuel economy but is also closely related to exhaust emissions and overall operational stability. An in-depth understanding of the role of the fuel pressure regulator helps us to carry out fault diagnosis more accurately, quickly locate the problem, and take effective measures to solve it. In this article, we will discuss the common failure performance of fuel pressure control valves, troubleshooting methods, and corresponding repair techniques, to provide comprehensive and practical guidance for automotive maintenance personnel and vehicle owners.

Ⅰ. Fuel Pressure Regulator Common Failure Performance

Lack of engine power: Failure of the fuel pressure regulator may lead to unstable fuel pressure. If the fuel pressure is too low, the fuel supply is insufficient, the engine burns insufficiently, and the power output will naturally be affected. For example, when the vehicle accelerates, as the fuel supply cannot keep up with the increase in engine speed, there will be a power lag phenomenon, which greatly reduces the driving experience.

Excessive Fuel Consumption: When the fuel pressure is too high, although the engine power output appears to be normal, there is too much fuel injection, resulting in fuel waste. In the long run, fuel consumption will increase significantly. According to statistics, a malfunctioning fuel pressure control valve may cause fuel consumption to be 10% – 20% higher than normal, bringing additional economic burden to vehicle owners.

Erratic or jerky idling: When the engine is idling, there is a greater demand for stability in the fuel supply. A malfunctioning fuel regulator can cause fuel pressure to fluctuate, resulting in unstable fuel injection, which in turn can cause erratic idling or body shaking. In this case, when the vehicle is parked or waiting at a traffic signal, the engine speed may go up and down or even stall, seriously affecting driving safety.

Ⅱ. Fuel Pressure Regulator Troubleshooting

1. Use the Fuel Pressure Gauge to Detect fuel pressure

This is one of the most direct and effective diagnostic methods. Connect a fuel pressure gauge to the pressure port of the fuelregulator, start the engine let it run under different operating conditions, and record the fuel pressure value. Normally, the fuel pressure should remain stable within the range specified by the manufacturer. If the pressure deviates by more than ±5% of the specified value, the fuel regulator is prima facie defective. For example, a brand of engine is specified to have a fuel pressure of 25 – 30 psi at idle. If the actual measured value is below 20 psi or above 35 psi, the fuel pressure control valve may not be functioning properly.

2. Check the Fuel Return Line

Check for clogs, kinks, and leaks in the return line. Clogging of the return line would mean that excess fuel cannot return smoothly to the fuel tank. Thus, it results in high fuel pressure. Leakage at the return line would cause too low fuel pressure. On checking during the process, first sight the fuel return line finding out if there is any visible damage or deformation. Next, find out whether the fuel return line is clear by disconnecting the return line and trying to blow through it with compressed air – there should be no part stopping airflow from passing through.

3. Check the vacuum line

For fuel pressure control valves with vacuum reference, the sealing and smoothness of the vacuum line directly affect the accuracy of fuel pressure regulation. Check the vacuum line for cracks, deterioration, or loose fittings. If the vacuum line is leaking, the regulator will not be able to accurately sense changes in the engine load, resulting in inaccurate fuel pressure regulation. The appearance of the vacuum hose can be visually inspected for cracks or bulges. At the same time, squeeze the vacuum hose with your hand to feel its softness and connection tightness. For suspected leaks, a special vacuum leak detection tool can be used for further inspection.

Ⅲ. Maintenance Tips

1. Clean the Interface of The Oil Return Pipe

In the maintenance process, first of all, you should clean the return pipe interface of impurities and dirt. Use a clean cloth to wipe the surface of the interface and clean it with the appropriate amount of detergent to ensure that there are no oil, dust, or other impurities left at the interface. Then, reconnect the fuel return pipe and tighten it with a clamp to prevent fuel leakage. When tightening the clamp, pay attention to the right amount of force, not only to ensure a tight connection, but also not to cause damage to the return pipe by excessive force.

2. Replacing a Defective Fuel Pressure Regulator

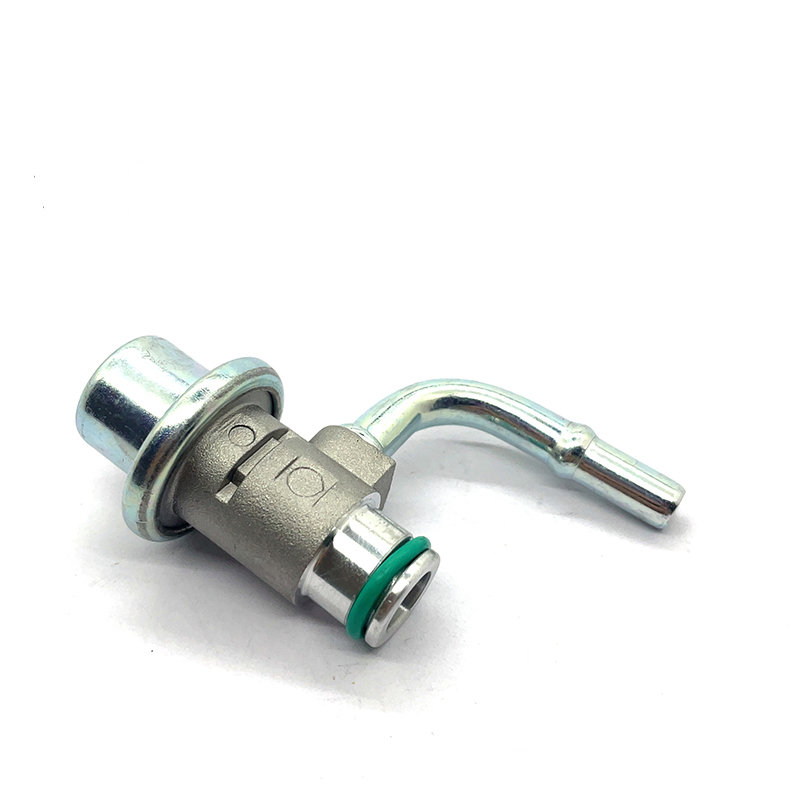

If it is confirmed after testing that the fuel pressure regulator is not functioning properly, replace it immediately with a new one. When selecting a replacement, make sure it matches the vehicle model and engine specifications. Fuel regulators of different makes and models may differ in structure, performance parameters, etc. The use of a mismatched regulator may result in more serious engine operation problems.

3. Maintenance Safety Reminder

The fuel system is flammable and explosive. Maintenance workers must obey safety rules. Release fuel system pressure before disconnecting parts to prevent fuel spray and fire. The repair site should be well-ventilated, with no open flames. Have fire-fighting equipment on hand. After repair, check for leaks, ensure normal fuel pressure, and confirm stable engine operation. If complex faults or uncertainty arise during repair, seek help from a professional.

Ⅳ. Conclusion

As a key component in the automotive fuel system, the normal operation of the fuel pressure regulator has a non-negligible impact on engine performance and vehicle safety. In practice, choosing the right fuel pressure regulator is an important step to ensure efficient engine operation. A suitable fuel pressure regulator can not only accurately maintain the pressure balance of the fuel system, but also avoid problems such as low engine power, high fuel consumption, and excessive exhaust emissions caused by abnormal pressure. Automotive service personnel and vehicle owners must have a thorough understanding of fuel pressure control valves and the correct selection method. This will not only help them deal with all kinds of faults more effectively but also ensure that the vehicle is always kept in good running condition, prolonging the life of the vehicle.