The fuel pressure regulator plays a vital role in the fuel system of an automobile engine. It not only affects the performance and efficiency of the engine but is also closely related to fuel economy and exhaust emissions. In this article, we will analyze the correct installation and debugging methods of the fuel pressure regulator to help you ensure the stable operation of the engine.

Ⅰ. Installation of Fuel Pressure Regulator

1. Preparation Before Installation

Before starting the installation, carefully read and understand the installation instructions. Ensure that the fuel system pressure is released to avoid dangerous situations such as fire or explosion caused by fuel leakage. It is recommended that the installation be carried out with the engine cool and the ignition switch off and that the necessary tools and equipment, such as wrenches, Teflon tape, etc., are available. Most manufacturers recommend installing a filter upstream of the regulator (some regulators have built-in filters) to prevent contamination of the valve seat by dust and particles. The regulating gas should be free of oil, grease, and other contaminants that could contaminate or damage the valve assembly or damage the regulator seals. The gas should also be free of excessive moisture or the regulator may freeze in high flow applications.

2. Determine Where to Install the Fuel Pressure Regulator

The fuel regulator should normally be mounted at the end of the fuel distribution line as close to the carburetor or fuel rail as possible, but avoid mounting on the exhaust manifold or other extremely hot surfaces. For dead-head regulators, are usually installed between the fuel pump and the carburetor, while bypass regulators, which return excess fuel to the tank, need to be installed with room for a return line connection. In automobile engines, the fuel pressure control valve is usually located above the fuel filter. Such a location helps it to effectively control the fuel pressure and ensure that the fuel can be supplied to the engine in the best condition.

3. Connecting Fuel Lines

Use Teflon tape to wrap the threads of the fittings and then tighten them with a wrench to ensure that there are no leaks in the connections. The standard regulator has two outlets. For dual carburetor installation, one outlet can be connected to each carburetor; for single carburetor installation, one outlet needs to be plugged. Connect the “out”side of the fuel pump to the “in”side of the regulator, making sure all fuel line connections are leak-free. If the ports are not labeled, contact the manufacturer to avoid incorrect connections. In some designs, internal components may be damaged if supply pressure is incorrectly supplied to the outlet port.

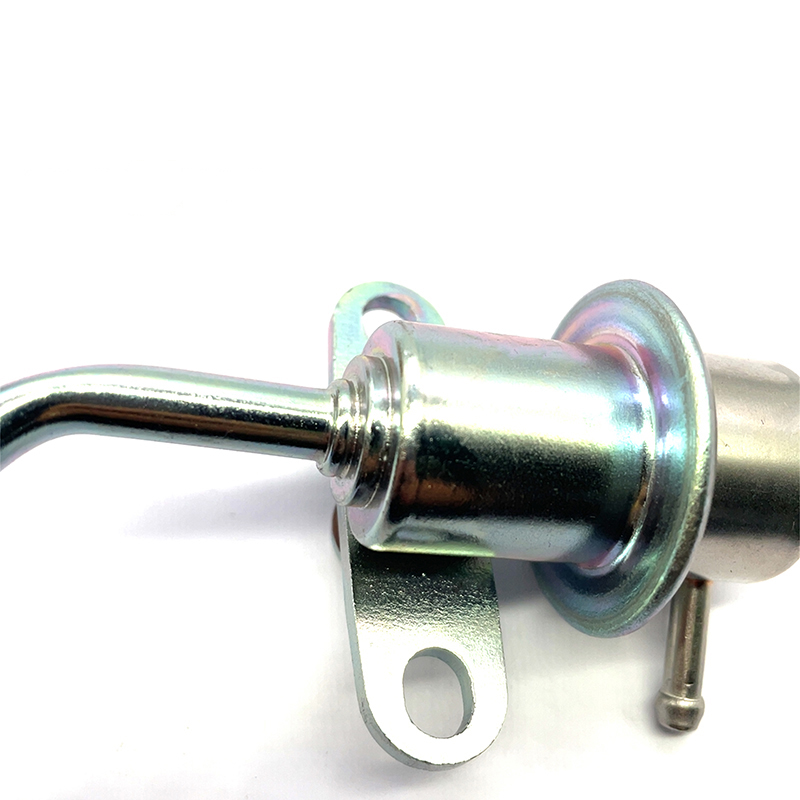

4. Mounting Brackets and Fuel Pressure Regulators

Secure the regulator in place using the supplied bracket and screws. If the regulator is supplied with a vacuum reference fitting, connect it to the engine’s vacuum source to provide more accurate pressure adjustment.

5. Install Pressure Gauge or Plug

Install a pressure gauge or plug in the regulator’s gauge port for subsequent pressure tuning. The threads of the pressure gauge port are typically 1/8-27 NPT.

II. Fuel Pressure Regulator Commissioning

Check For Leaks: After completing the installation, start the engine and check all connections for fuel leaks. If there is a leak, immediately shut down the engine and fix the problem before continuing with commissioning.

Adjusting Pressure: The regulator is usually preset at the factory but can be adjusted to suit. Loosen the lock nut at the top of the regulator and use a suitable tool (e.g., 1/8-inch Allen wrench) to turn the adjusting screw clockwise to increase the pressure and counterclockwise to decrease it. Operate slowly during adjustment and monitor the pressure gauge reading in real time until the desired fuel pressure is achieved.

Recheck the pressure: After the adjustment is completed, start the engine again and let it run for a period of time to ensure that the fuel pressure stabilizes at the set value. At the same time, check the sealing and overall working condition of the regulator to confirm that there is no abnormality and, the commissioning can be completed.

Ⅲ. Precautions for installation and commissioning

1. Safety First

In the entire installation and commissioning process, safety is crucial. Ensure that the installation is carried out in a non-pressurized state to avoid fuel spattering and fire. If there is any uncertainty during installation, it is recommended to consult a professional or contact the regulator manufacturer’s technical support.

2. Obey the Manufacturer’s Instructions

Different brands and designs of fuel pressure regulators might have certain rules for installing and setting them up. Always obey the instructions and advice given by the manufacturer to ensure it is fitted properly and to get the best performance from the regulator.

3. Regular Checkups

After it is installed, routine checkups on the regulator are important to maintain its long-term stable operation. It is advisable to visually inspect critical connections of the regulator (vacuum ports, fuel line connections, and seals) every 15,000 – 20,000 kilometers or annually to preclude the risk of unstable pressure as well as fuel leakage due to the looseness, damage, or deterioration of these parts. Also, when cleaning the regulator housing, avoid using corrosive cleaning agents that could damage the seals and housing coating. Check the engine compartment regularly and look out for signs of fuel leaks. Staying sensitive to the condition of your vehicle is key to ensuring the long-term health of your fuel system. Click here for fuel pressure regulator repair tips.

Ⅳ. Conclusion

Proper installation and commissioning of the fuel pressure control valve regulator is essential to ensure engine performance and stable operation of the fuel system. By carefully following the above steps and precautions, you can optimize engine performance, improve fuel economy, and reduce exhaust emissions by selecting and installing a suitable fuel pressure regulator for your vehicle.